Diamond products have long been the go-to tools for cutting, grinding, and drilling various materials. But have you ever wondered how these products actually work? In this blog post, we will take a closer look at the inner workings of diamond products and unveil the secrets behind their impressive performance.

The key to the effectiveness of diamond products lies in their unique construction. Before leaving the factory, the cutting segments of blades, cores, or grinding heads undergo a grinding process. This process removes a layer of the metal bond, exposing the diamonds. Once on-site, these tools are ready for immediate use.

Several factors play a crucial role in determining the performance of a blade or core bit:

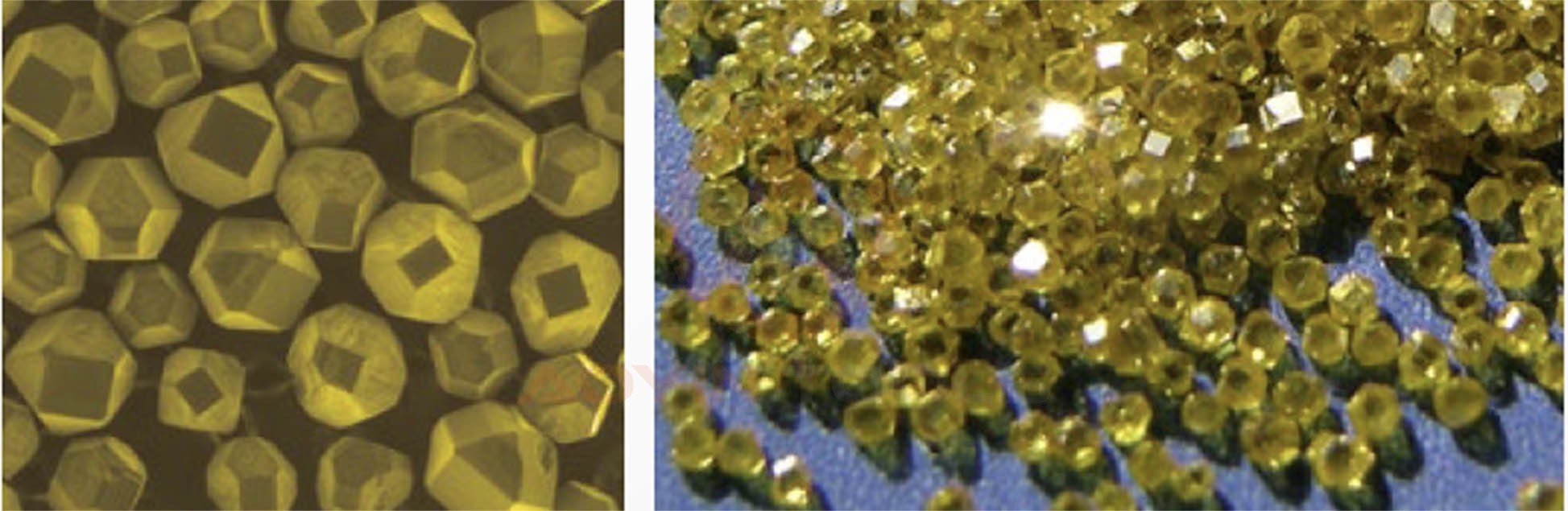

1. Type and Size of Diamond Crystals: Diamonds come in different types and sizes. Generally, larger diamond crystals are better suited for softer aggregate types, while smaller diamond crystals excel in harder aggregates. The size and shape of the diamond crystals directly impact their cutting efficiency.

2. Diamond Concentration: Diamond concentration refers to the amount and dispersion of diamond grit in the segment. A higher concentration of diamonds, with closer spacing of the grit, results in a harder segment. Highly concentrated diamond segments outperform those with lower concentrations.

However, the quality, size, and shape of the diamond crystals also influence the performance. The bond or matrix, designed to wear away proportionately with the blunting, breaking off, or pulling out of the diamond crystal, is a critical component of diamond products.

The wear of a diamond segment occurs in four phases:

- Phase 1: Bond Diamond Quality

- Phase 2: Diamond Wear

- Phase 3: Diamond Fracture

- Phase 4: Diamond Pull Out

These phases of wear should align with the abrasive properties of the aggregates being worked on.

But how does the actual grinding work?

1. When a diamond product is in use, the exposed diamond crystals held in place by the metal matrix or bond perform the grinding task. Each diamond is supported by a bond tail, which trails behind it. As the blade rotates through the material, the exposed diamonds on the surface grind the material away.

2. With each rotation, the exposed diamonds undergo stress and start to crack and fracture, while the bond begins to wear away gradually.

3. Over time, the diamonds fracture completely and are swept away along with the ground material. In wet grinding, this mixture of material and water forms a slurry.

4. As a diamond gets pulled out, the bond continues to wear away, revealing another diamond. This cycle repeats until the segment is worn down to the core.

Diamond products harness the incredible hardness and durability of diamonds to cut through various materials effortlessly. Manufacturers carefully balance the characteristics of diamond crystals, concentration, and bond to achieve optimal performance in different applications. Continuous research and development lead to the creation of innovative bonding formulas, ensuring that diamond products maintain their position at the forefront of the industry.

In conclusion, understanding the inner workings of diamond products provides us with valuable insights into their exceptional cutting abilities. The combination of diamond crystals, concentration, and bond ensures efficient and precise results in diverse cutting, grinding, and drilling applications.