MCNC-5X, a cutting-edge CNC Bridge Stone Cutting and milling machine. With its 5-axis control and user-friendly Graphical CNC system, this machine offers precise and efficient operations. Equipped with a 15" color touch-screen, it ensures a hassle-free working experience. Perform milling, cutting, drilling, and engraving with ease, all in one versatile package.

Color :

CustomizedShipping Port :

Xiamen PortLead Time :

7-35 days after paymentCustomized support :

Visualization ServiceBrand Name :

OEMCNC Bridge Stone Cutting and Milling Machine MCNC-5X

The CNC bridge type stone cutting and milling machine MCNC-5X, a revolutionary tool that combines advanced technology with ease of use. This innovative machine is designed to increase the efficiency and precision of cutting and milling processes, making it ideal for complex machining tasks.

|

Technical Parameter of MCNC-5X |

||

|

Diameter of saw blade |

mm |

Ф350~Ф500mm |

|

Dimension of working platform |

mm |

3500X2000mm |

|

Max. cutting length |

mm |

3500 |

|

Max. cutting width |

mm |

2000 |

|

Max. cutting thickness |

mm |

140 |

|

Max. lifting stroke |

mm |

600 |

|

Power of main motor |

Kw |

15 |

|

Gross power |

Kw |

29.5 |

|

Water consumption |

m3/h |

2 |

|

Gross weight |

kg |

6000 |

|

Dimensions (L x W x H) |

mm |

5800X3200X3800 |

|

Power Input |

|

380V 50Hz |

Main Features

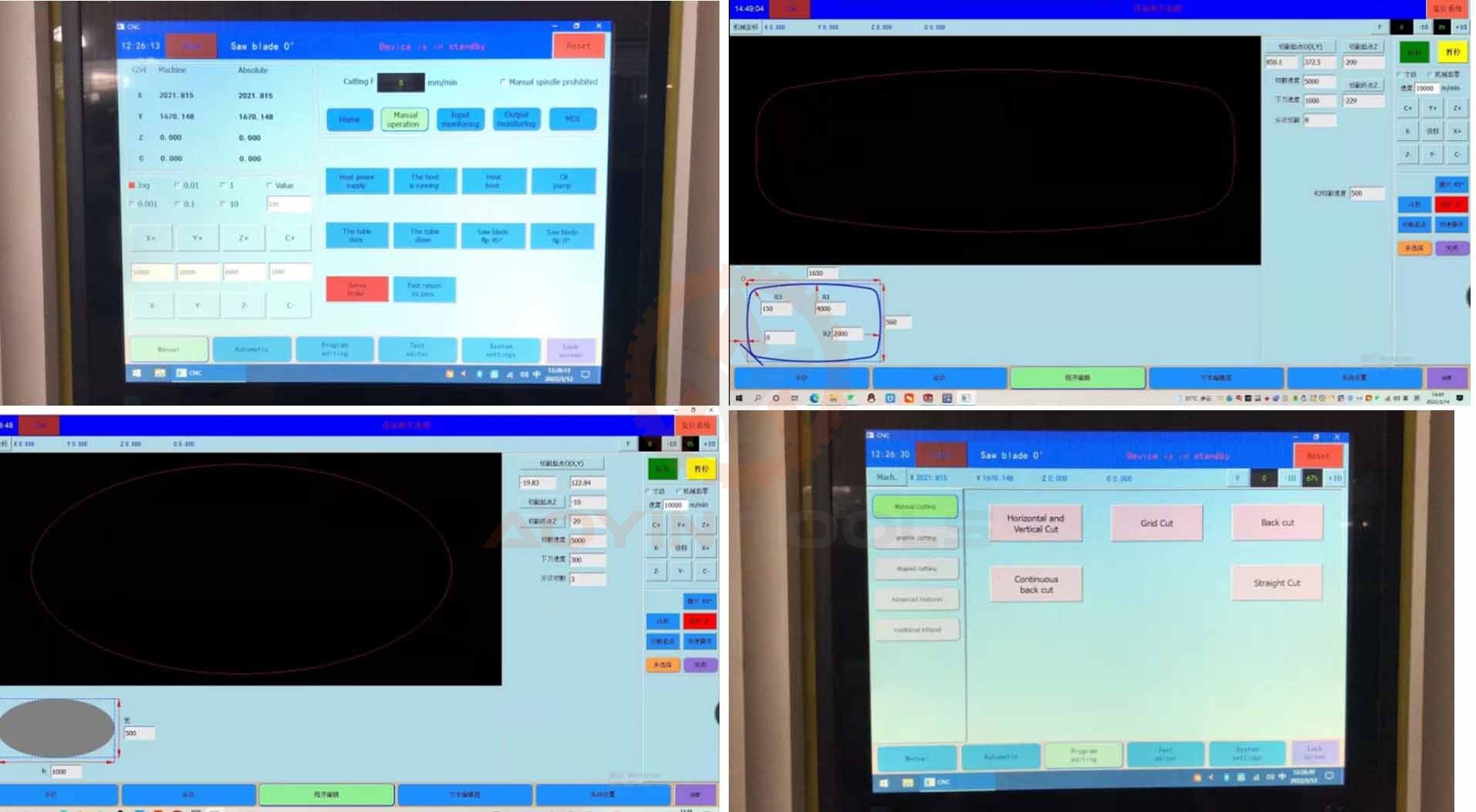

1) 5 axis control with Graphical CNC system.

2) Easy to use interface with 15" color touch-screen.

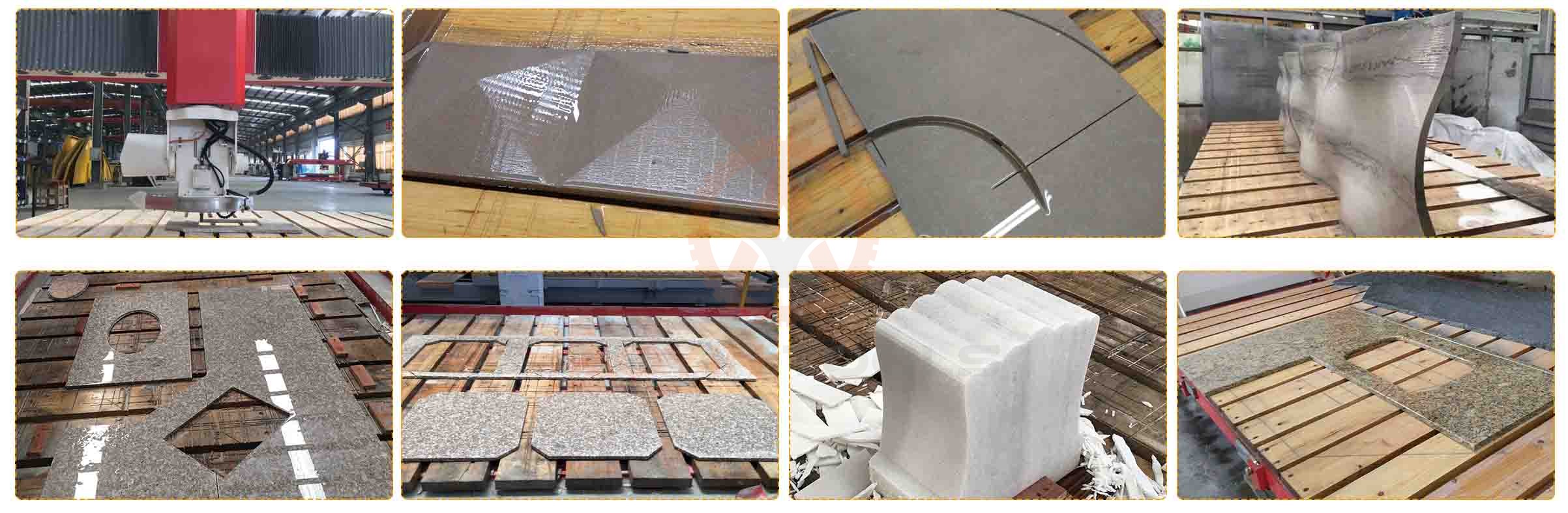

3) Combine functions of milling, cutting, drilling, engraving into an organic whole for complex processing.

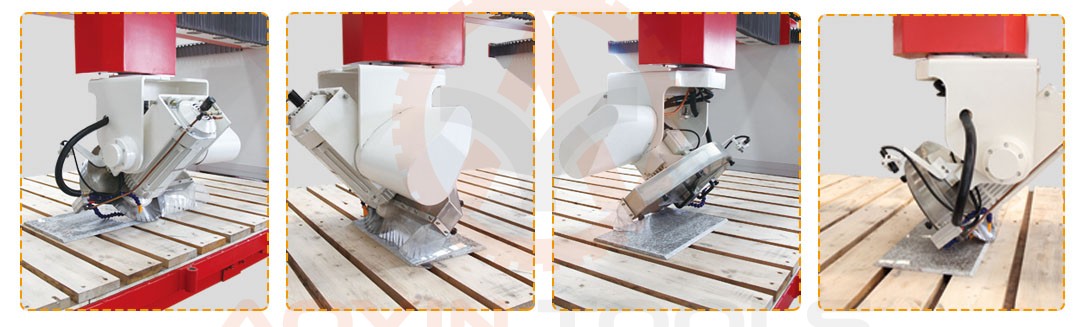

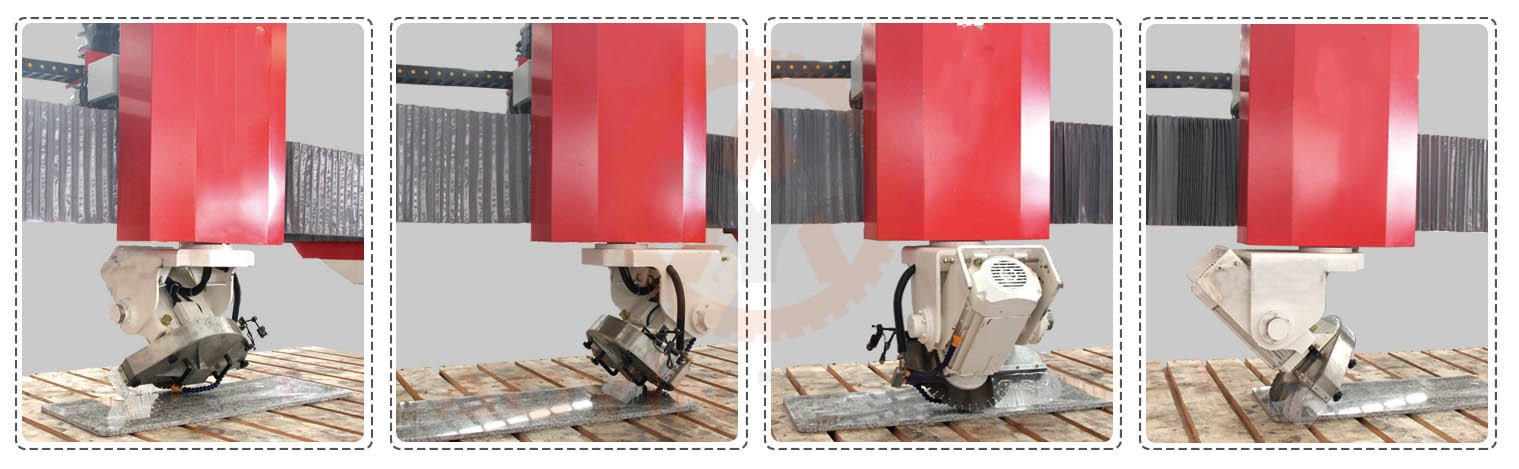

4) Blade can rotate 0°-360° and tilt 90° at any direction and any angle chamfering cutting.

5) Worktable can tilt 85°, easy for slabs loading and unloading.

6) Manual cuts available for simple machining.

Control system -- CNC

Top of the line CNC system with touch screen for easy setting and automatic processing. It can make a complicated machining job easy, perfect and high efficient.

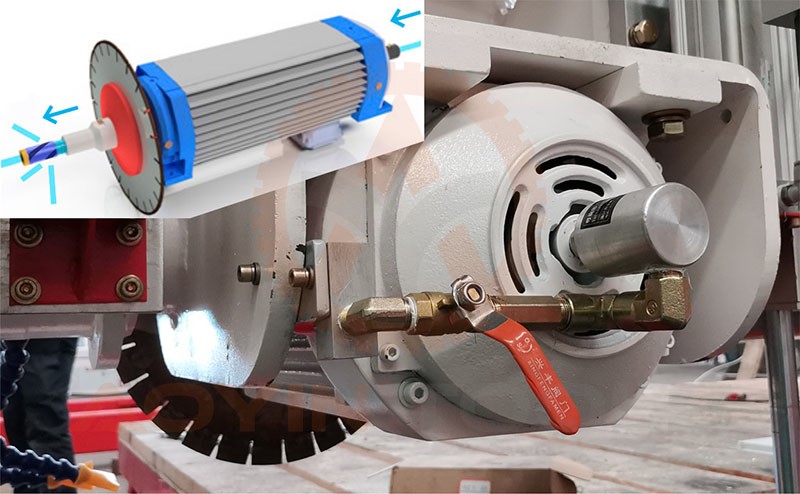

Digital Servomotor

The servo motor of Japanese Yaskawa brand is adopted, which has high performance and precision to ensure the cutting of different shapes.

Electro-spindles

of high quality controlled by an inverter allowing the adjustment of the nr. of revolutions from 0 to 6000 rpm, so granting the use of blade and diamond tools such as a core drill or milling cutter. The tool change is of manual type.

Internal water passage

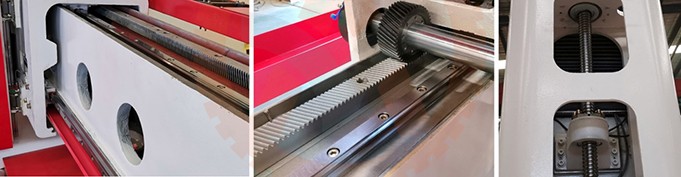

Linear Guide

Brand: Hiwin Original: Taiwan, China

Famous products, top quality used on crossbeam and carling for high precision of cutting and long lifespan.

FAQ:

1. How to control the MCNC-5X machine?

MCNC-5X is equipped with 5-axis control system and graphical CNC interface. You can easily navigate and control the machine using the 15-inch color touch screen.

2. Can MCNC-5X perform complex machining tasks?

Absolutely! The MCNC-5X combines milling, cutting, drilling and engraving functions into a single machine that can perform complex machining tasks.

3. Can MCNC-5X handle different angles and directions?

Yes, the blade of the MCNC-5X can be rotated from 0° to 360° and tilted up to 90°, allowing chamfer cutting in any direction and angle.

4. Is it convenient to install and remove the plate on MCNC-5X?

really! The workbench of MCNC-5X can be tilted up to 85°, making loading and unloading plates easy and convenient.

5. Can I perform manual cutting on the MCNC-5X?

Absolutely! The MCNC-5X offers a manual cutting option for simple machining tasks.